clamp on flow meter accuracy

Clamp-on flow system for the measurement of liquids oil or gas. About 50 of these are differential pressure flow meters 40 is the liquid flow sensor and 20 are Ultrasonic Level Transmitter and mass flow meter.

Thermtest has rigorously engineered the Heat Flow Meter HFM to meet the requirements of international standards including ASTM C518 ISO 8301 and EN 12667.

. Gas bubbles in liquid. Suitable for new installations as well as retrofitting. Sino-Inst offers over 50 flow meter for flow measurement.

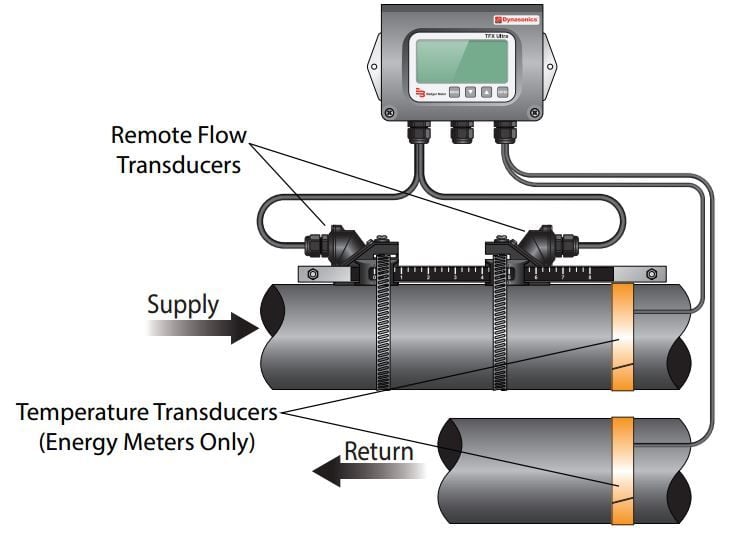

Since most flow meters that sense velocity are sensitive to turbulence they must be installed at a specific point within the process pipeline that contains a length of straight rigid pipe that is long enough to ensure laminar flow so that the meter is able to provide stable accurate readings. Mastercraft Digital Clamp Meter provides auto range with measurement of ACDC voltage AC Current resistance diode check and continuity check data hold function. A market leading process measurement device the VersaFlow Clamp-On Ultrasonic flow meters are designed for applications where a customer is unwilling or unable to cut into the process measurement line to install an in-line meter.

Operating the HFM is straightforwarda sample is positioned between two heating cooling plates and the upper plate powered by stepper motors positioned in each corner lowers to contact the top of the. Liquid droplets in gas vortex meter accuracy will drop because of the meters inability to differentiate between the phases. To meet this need SmartMeasurement offers the.

High accuracy repeatability and zero flow detection. A wide variety of flow meters options are available to you such as free samples paid samples. Hydraulic oil flow in a hydraulic press coolant flow to a critical piece of machinery natural gas flow to a burner or heater lubrication flow to a bearing and chemical injection dosing are but a few examples.

Available in configurations for pipe line sizes from DN15 to DN4000 12 to 160 the clamp-on design offers a cost-effective means of. Wet low-quality steam is one such application. The following chart.

Downward compatible with all sensors of. Display accuracy with 2000 counts. Comes with carry bag to protect device.

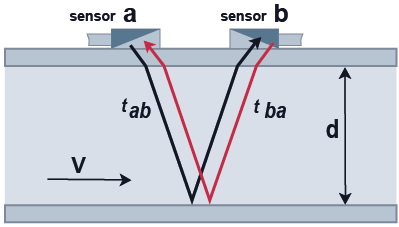

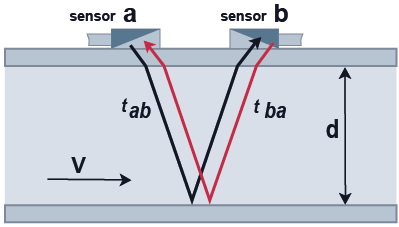

When measuring multi-phase flow solid particles in gas or liquid. In the flowmeter industry this is referred to as a straight-run requirement. Designed for use with up to 4 paths.

Fast signal processing with 100 Hz update rate. Comes with test leads to allow customers to only need one meter for a wide range of tasks. Designed for use in Ex areas safe distance to transmitter of up to 150 m.

The liquid phase should be homogeneously dispersed within the steam and vertical flow lines should be. Advances in industrial automation have driven the need for more intelligent and more high-precision fluid measurement.

Pin Op Comate Digital Vortet Flowmeter

.jpg)

What To Consider When Selecting A Flow Meter

Does Reynolds Number Affect Flowmeter Accuracy Sino Inst In 2021 Reynolds Number Flow State Fluid Flow

Frequently Asked Questions About Ultrasonic Clamp On Flowmeters